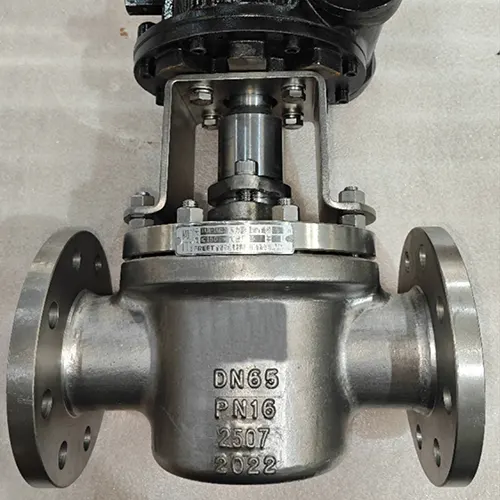

Special Material Plug Valve

Size Range: DN15~900mm / NPS1/2"~36"

Pressure: PN2.0~26.0MPa / Class150~1500

Material: A105, LF2, F304, F316, F304L, F316L, F51, WCB, LCB, WCC, CF8, CF8M, CF3, CF3M, A890 4A etc

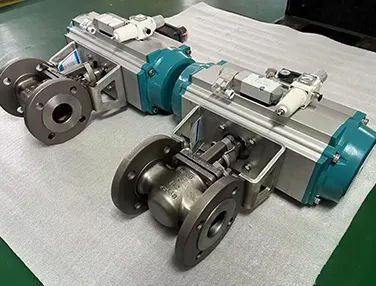

Operation: Manual, Worm Gear, Hydraulic, Electric, Pneumatic

Standard: ANSI, API, DIN, EAC, JIS, CE, ISO, EN, GB

Applications: Strongly Corrosive Media Such As Sulfuric Acid And Hydrofluoric Acid, High-Temperature Brine In Geothermal Wells, Slurries With High Solid Content, And Pharmaceuticals

Advantages: Corrosion-Resistant Alloys: Hastelloy, Monel, Titanium And Titanium Alloys; High-Temperature Alloys: Inconel, Stainless Steel Variants; Non-Metallic Materials: Ceramics (Alumina, Silicon Carbide), Ceramics (Alumina, Silicon Carbide)

Description

Special Material Plug Valve is a valve made of non-standard or high-performance materials, mainly used in harsh working conditions (such as high temperature, high pressure, corrosive media, etc.). Its core design controls the flow of fluid by rotating the conical or cylindrical plug body. The application of special materials significantly improves corrosion resistance, wear resistance or extreme temperature adaptability.

Special Material Plug Valve Gallery

Quality Control

Apply advanced computer simulation analysis technology

API 6D, CE certification, ISO 9001, ISO 14001, ISO 45001

Ensure the safety and reliability of the project system

Environmental Protection, make world sustainable