Metal Seat Plug Valve

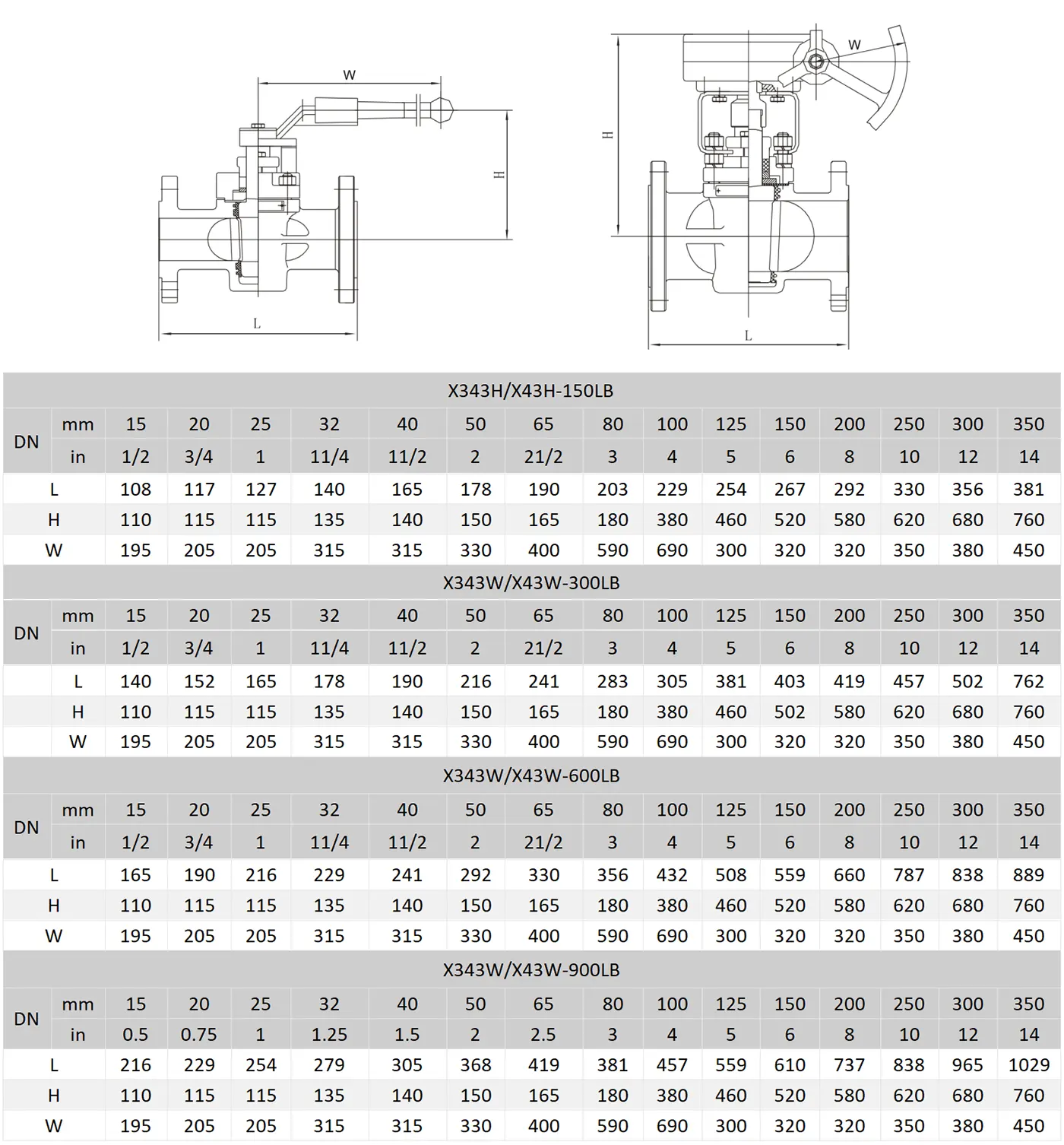

Size Range: DN15~1600mm / NPS1/2"~64"

Pressure: PN0.6~42.0MPa / Class150~2500

Material: A105, LF2, F304, F316, F304L, F316L, F51,WCB, LCB, WCC, CF8, CF8M, CF3, CF3M, A890 4A etc

Operation: Manual, Worm Gear, Hydraulic, Electric, Pneumatic

Standard: ANSI, API, DIN, EAC, JIS, CE, ISO, EN, GB

Applications: High-Pressure Oil And Gas Transportation, Shale Gas Extraction, Lng Ultra-Low Temperature System, Chemical And Petrochemical, Thermal Power Plant Steam System, Slurry Transportation, Blast Furnace Gas System

Advantages: High Pressure Resistance, High Temperature Resistance, Wear Resistance, Tight Sealing Performance, Excellent Anti-Scouring Performance, Reliable Safety Performance

Description

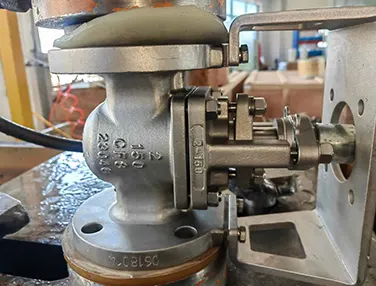

Metal Seat Plug Valve uses a precision-machined conical plug and a hardened metal seat to form a rigid seal pair, and achieves zero leakage through a unique pressure-tightening structure. It has excellent wear resistance and self-cleaning sealing surface under high temperature, high pressure and particle-containing media conditions, and is suitable for harsh working conditions in the fields of petroleum, natural gas, and chemical industry.

Metal Seat Plug Valve Gallery

Technical Parameters

Quality Control

Apply advanced computer simulation analysis technology

API 6D, CE certification, ISO 9001, ISO 14001, ISO 45001

Ensure the safety and reliability of the project system

Environmental Protection, make world sustainable