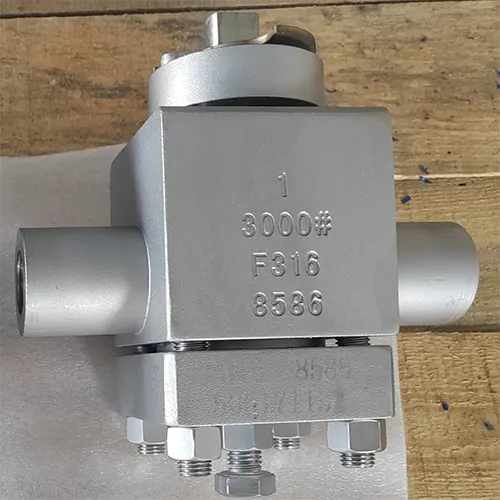

Forged Integrated Plug Valve

Size Range: DN15~300mm / NPS1/2"~12"

Pressure: PN0.6~42.0MPa / Class150~2500

Material: A105, LF2, F304, F316, F304L, F316L, F51, WCB, LCB, WCC, CF8, CF8M, CF3, CF3M, A890 4A etc

Operation: Manual, Worm Gear, Hydraulic, Electric, Pneumatic

Standard: ANSI, API, DIN, EAC, JIS, CE, ISO, EN, GB

Applications: Chemical/Petrochemical (Corrosive Media Such As Sulfuric Acid, Hydrochloric Acid, Sodium Hydroxide, Etc.), Water Treatment, Pharmaceutical/Food, Metallurgy/Electroplating

Advantages: Excellent Corrosion Resistance (Can Withstand Strong Acids, Alkalis, Organic Solvents And Other Corrosive Media), Anti-Pollution, Low Flow Resistance, Easy Maintenance

Description

Forged integrated plug valves utilize a forging process to manufacture their valve bodies (and key components). They control fluid flow or flow by rotating an internal plug (spool). The forged integrated plug valve body, made of carbon steel, stainless steel, or alloy steel, achieves a dense, high-strength structure after forging. Suitable for demanding operating conditions such as high pressure, high temperature, and severe corrosion, they offer fast opening and closing, reliable sealing, and a compact structure.

1. High Strength and High-Pressure Resistance: The forging process eliminates internal defects, making the valve body impact- and fatigue-resistant. It can withstand high pressures (PN16-PN420) and a wide temperature range (-29°C to 550°C), making it suitable for demanding applications such as oil and gas, power generation, and hydraulics.

2. Excellent Sealing Performance: Soft seals achieve "zero leakage" (Class V), while hard seals meet low-leakage standards (Class IV), making them suitable for applications involving toxic and precious media or demanding sealing requirements.

3. Quick and Effortless Operation: The plug can be fully opened or closed with just a 90° rotation, offering fast opening and closing speeds, low torque, and easy manual operation, reducing actuator costs.

4. Compact and Space-Saving Structure: The one-piece forged valve body is compact and lightweight (20%-30% lighter than cast valves), making it suitable for installation in space-constrained environments such as ships and narrow pipelines.

5. Corrosion Resistance and Long Life: Optional corrosion-resistant materials such as stainless steel and Hastelloy alloy are available, and surface hardening treatment enhances wear resistance, extending the service life by over 30% compared to ordinary cast valves.

6. Low Flow Resistance and Excellent Flow: The full-bore design ensures smooth flow of media, with a low flow resistance coefficient (ζ<0.5), making it suitable for high-viscosity fluids or precision systems sensitive to flow resistance.

Forged Integrated Plug Valve Gallery

Quality Control

Apply advanced computer simulation analysis technology

API 6D, CE certification, ISO 9001, ISO 14001, ISO 45001

Ensure the safety and reliability of the project system

Environmental Protection, make world sustainable