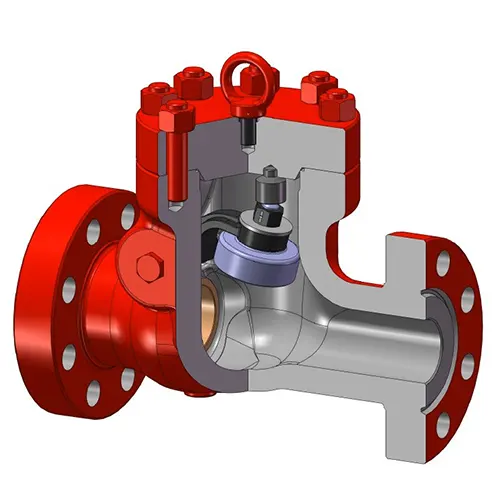

API 6A Check Valve

Size Range 1-13/16"~7-1/16"

Pressure: 2000psi~20000psi

Temperature -60℃~121℃

Material AA~HH

Performance PR1~PR2F

Standard API 6A, DIN, EAC, JIS, CE, ISO, EN, GB

Advantages API 6A-certified, compact, anti-backflow, high-pressure/corrosion-resistant wellhead safety

Description

Check valves are passive safety valves designed to prevent backflow of media, which can cause wellhead pressure disturbances, equipment damage, and even safety accidents. They act as a "backflow prevention barrier" for wellhead systems.

Check valves allow only unidirectional flow of media. They automatically close when the downstream pressure is higher than the upstream pressure, preventing problems such as pump reversal, wellbore pressure fluctuations, and manifold pressure buildup caused by backflow.

Check valves are sensitive to opening and closing, provide reliable sealing, are resistant to high-pressure impacts, require no manual operation, and can be installed in series with gate valves to form double protection.

Check valves are used at the inlet of wellhead production pipelines and injection wells (water/gas injection pipelines) to prevent the injected media from flowing back and contaminating the wellbore.

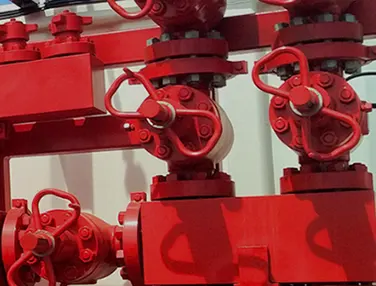

API 6A Check Valve Gallery

Quality Control

Apply advanced computer simulation analysis technology

API 6D, CE certification, ISO 9001, ISO 14001, ISO 45001

Ensure the safety and reliability of the project system

Environmental Protection, make world sustainable