Application Of Thermal Insulation Jacketed Plug Valve In Low Temperature Environment In Winter

In petroleum, chemical, natural gas, and pharmaceuticals, industrial valves as a key equipment in the fluid control. It's performance will directly influence the whole production system stability and safety. In the winter, low temperature environment, normal valves are prone to failure due to freezing of the medium, material embrittlement, or seal failure , thus influencing the normal production. Jacket Plug Valve can effectively face the low-temperature enlivenment challenge because of its unique insulation design, which make it become the ideal choice in cold working condition.

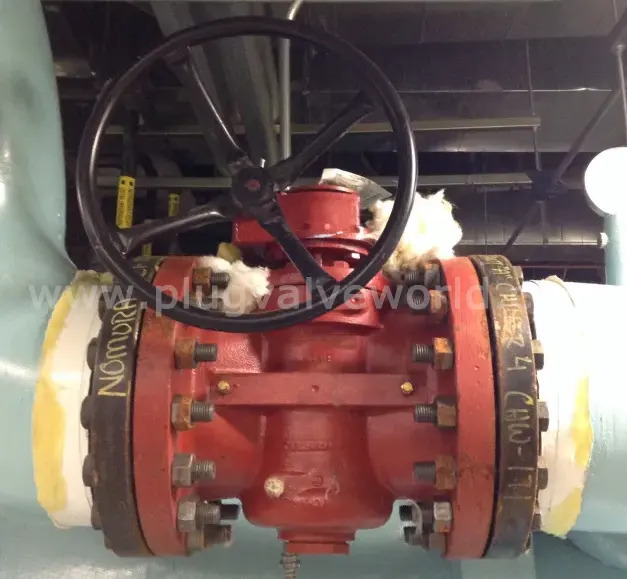

1. Structure and Operating Principle of the Insulated Jacketed Plug Valve

1.1 Basic Structure

Jacket Plug Valve is a special valve, adding an insulation layer or jacket structure on the basis of the traditional plug valve. And its main parts including:

Body: Usually made of low-temperature resistant materials such as cast steel and stainless steel, ensuring that it is not easy to cracking in cold environments.

Plug (valve core): Conical or cylindrical design, controlling the flow or shutoff of media through rotation.

Thermal insulation jacket: A sandwich structure wrapped the outside of body, and introduce heat media such as steam, hot water or heat transfer oil to prevent the fluid inside the valve from freezing.

Sealing system: Low-temperature resistant materials (such as polytetrafluoroethylene, PTFE) are adopted to ensuring sealing performance.

Drive method: Manual, electric or pneumatic operation mode, suitable for different working conditions.

1.2 Working Principle

Thermal insulation jacketed plug valves is opened and closed by rotating the plug 90°. Its jacket is connected to the external insulation system, and allow heat sources (such as steam or electric tracing) to maintain the temperature of the valve body, prevent the medium from freezing or icing due to low temperatures, which ensure that the valve remains flexible in extremely cold environments.

2. Challenges of Winter Low-Temperature Environments on Valves

In low temperature environment, common valves the following problems may be faced:

Media Freezing: Water, oil or other easily condensable medium may freeze at a low temperatures, which will cause the valve stuck or cannot close.

Material Embrittlement: Some metal or plastic become vulnerable at a extremely low temperatures and easy to cracking or leakage.

Seal Failure: Rubber or common polymer seals harden at low temperatures and lose elasticity, increasing the risk of leakage.

Difficult Operation: Low temperatures increase the viscosity of the lubricant, increasing the torque for open and close the valve, and make manual operation difficult.

Insulated jacketed plug valve effectively solve the issues through active insulation technology, to ensure reliable operation of the valve under low-temperature conditions.

3. Advantages of Insulated Jacketed Plug Valves in Low-Temperature Environments

3.1 Preventing Freezing of Media

In cryogenic media transport system like petroleum and liquefied natural gas (LNG), Insulated jacketed plug valve can keep the body temperature through external heat source, like steam or electric heating, preventing the medium from freeze in the valve body and ensuring the fluid flows smoothly.

3.2 Improving Material Adaptability

Insulated jacketed plug valves are usual made of cold-resistant materials such as stainless steel and low-temperature carbon steel(LCB). By integrate insulation measure, the material can be prevented from becoming brittle due to low temperatures, extending the service life of the valve.

3.3 Enhanced Sealing Performance

Using PTFE or other cold-resistant sealing materials, combining with thermal insulation measures, ensures that the seal maintains good elasticity in low-temperature environments, reducing the risk of leakage.

3.4 Reduced Operating Torque

The thermal insulation design prevent the lubricant from freezing, make the valve opening and closing more flexible and reduce operational difficulty. It is particularly suitable for automatic control system.

3.5 Adaptable to Various Insulation Methods

Steam tracing: Suitable for applications where industrial steam is available, have high efficiency and cost-effectiveness features.

Electric tracing: Suitable for remote areas without a steam source, achieveing precise temperature control.

Hot water circulation: Suitable for applications requiring stable temperature, such as chemical reaction systems.

4. Typical Application Scenarios

4.1 Oil and Gas Industry

In low-temperature environments for example northern oil fields and LNG receiving station, insulated jacketed plug valves are used in crude oil and natural gas pipeline to prevent the medium from solidification due to low temperaturs, ensuring safe transportation.

4.2 Chemical Industry

In low-temperature storage or freeze-drying processes, insulated valves can ensure the hygiene of the fluid and prevent product quality from being affected by temperature fluctuations.

4.3 Food and Pharmaceutical Industries

In low-temperature storage or freeze-drying processes, insulated valves can ensure the hygiene of the fluid and prevent product quality from being affected by temperature fluctuations.

4.4 Municipal Heating Systems

In urban heating networks, the insulated jacketed plug valve can prevent hot water from freezing and ensure stable heating.

5. Conclusion

Insulated jacketed plug valve, by virtue of its excellent thermal insulation performance and cryogenic design, and becoming a key equipment for fluid control in severe winter environment. It is widespread application in petroleum, chemical, natural gas industries , which effectively resolve problems like freezing of cryogenic media, material embrittlement, and seal failure, hence enhancing the safety and reliability of production systems. In the future, with advancing in material science and insulation technology, the insulated jacketed plug valve will play a more important role in cryogenic applications.

Previous: Steam Jacketed Plug Valve: Efficient and Durable Fluid Control Solution