PTFE and PFA Lined Plug Valves for Extreme Conditions

PFA lined plug valves are made of meltable PTFE lined plug valves, while PTFE lined plug valves are made of PTFE lined plug valves. Although their sealing materials are similar, there are differences between the two. However, both types of valves offer corrosion resistance, high purity, and temperature resistance, making them widely used in high-end industries such as semiconductors, chemicals, and pharmaceuticals. Their core functionality relies on a unique rotating seal structure, ensuring no leakage of the medium during opening and closing.

PFA is an upgraded modified material of PTFE, so while retaining the excellent physical and chemical properties of PTFE, its cold flow properties have been improved, and its melt viscosity has been significantly reduced, enabling processing via conventional methods such as compression molding, extrusion molding, and injection molding. PTFE exhibits excellent mechanical properties across a wide temperature range from low to high temperatures (-80°C to 260°C) and has high impact strength. PFA has a melting point of 300-310°C and a molding temperature of 350-410°C, with excellent processing characteristics. PFA retains most of PTFE's advantages while enabling melt processing. However, its drawback is that PFA is relatively expensive in terms of cost and price.

Ⅰ. Lined Plug Valves Properties

Size range: 1/2“-60” (DN15-DN200)

Pressure rating: 0.1 mbar-16 bar / ASME CLASS 150/300/600

Lining material: PFA, PTFE, FEP, ETFE

Operating temperature: -196°C to 260°C

Valve body material: ASTM A216 A351 CF8, etc.

Reference standard: API 594

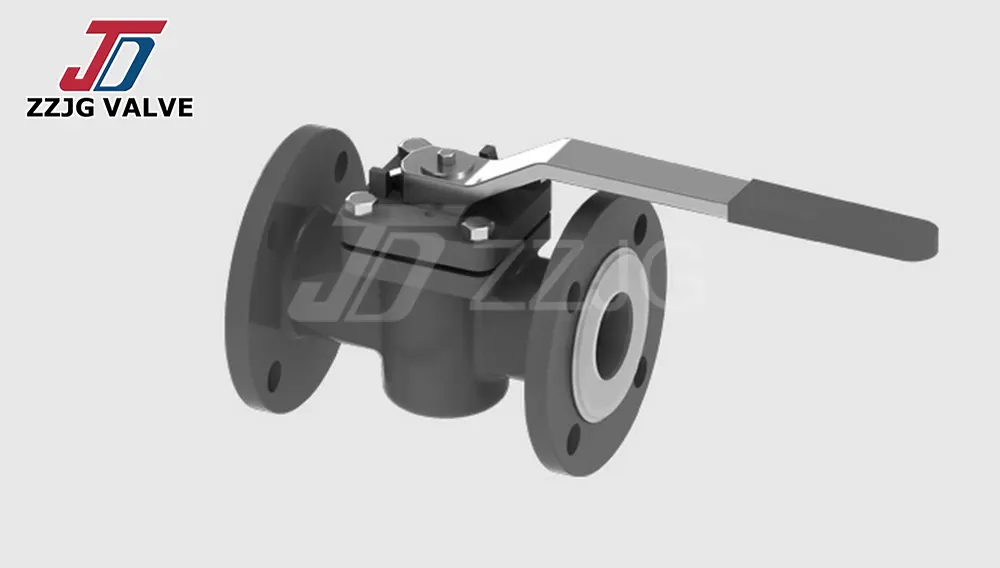

Ⅱ. Lined Plug Valves Structure

PTFE and PFA lined plug valves primarily consist of a valve body, plug, valve stem, and sealing components: The valve body is manufactured using PTFE or PFA material through injection molding or lining processes to ensure corrosion resistance. The plug is typically conical or cylindrical in shape, with a precision-polished surface, forming a dynamic sealing surface with the valve seat. The sealing assembly includes a valve seat seal ring (PFA or reinforced PTFE) and an elastic compensation structure (such as a spring or O-ring). Plug valves core feature is the ability to open or close the flow path by rotating the plug 90°, with sealing performance dependent on the precision of the plug-to-seat fit and material properties.

Ⅲ. Extreme Condition Adaptability of Lined Plug Valves

High Temperature (>200°C): Uses glass-fiber-reinforced PFA to prevent softening and deformation.

Low Temperature (<-50°C): Optimizes the cone angle design to avoid material brittleness at low temperatures, which could cause leakage.

The rotational sealing performance of PTFE and PFA lined plug valves relies on a comprehensive design combining precise conical surface matching, elastic compensation, and material optimization. With advancements in new materials and manufacturing technologies, their sealing reliability and durability will further improve, providing superior fluid control solutions for high-end industrial applications.

Previous: Application Of Thermal Insulation Jacketed Plug Valve In Low Temperature Environment In Winter

Next: Lubricated vs Non-Lubricated Plug Valves for Saudi Market