Steam Jacketed Plug Valve: Efficient and Durable Fluid Control Solution

1. Product Introduction

Steam Jacketed Plug Valve is special valve, designed for high-viscosity, easily solidifying or high-temperature media, and play a key role in the control of high-temperature fluids in industries such as petrochemicals, food processing, and pharmaceuticals.

The steam jacketed plug valve adopt a external steam heating technology, ensuring medium keep a constant temperature, effectively preventing asphalt, heavy oil, resin and other easily solidifying media clog the pipes. This also help enhance improve the stability and efficiency of the production process. Compared to normal plug valves, steam jacketed plug valve especially suitable for the industrial sites which need accurate temperature control. It is an indispensable key equipment in modern process industries.

2. Operating Principle

The core of the steam-jacketed plug valve is it unique jacket heating system. Steam or thermal oil circulates through the outer jacket of the valve body, maintain the valve body and the internal medium at a optimal operating temperature. The design is particularly suitable for transport high-viscosity media, such as in asphalt production or chemical reactions, by preventing the medium from solidifying due to temperature drops.

The steam jacketed plug valve rotates the conical or cylindrical plug to achieve open and close. Plug and Seat adopts a precisely fitted metal hard seal or PTFE soft seal structure to ensure reliable sealing performance under high pressure and temperature conditions. The operation methods are various, like handle, worm gear, electric, and pneumatic actuator, meeting various industrial automation needs. Additionally, optimized steam passageway design improve heat exchange efficiency, lower energy loss, making the steam jacketed plug valve become a outstanding energy-saving choice.

3. Core Technologies

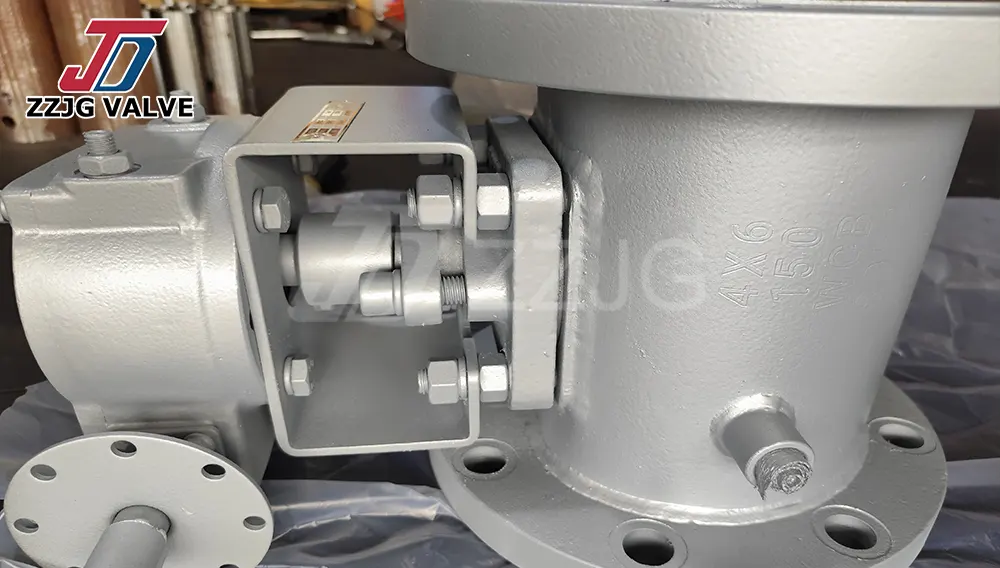

3.1 Jacket Design

High performance of the steam jacketed plug valve from multiple key technologies, among which the design of the jacketed heating system is particularly crucial. The seamless steel pipe or integral cast jacket structure is adopted. The jacket is welded between the two flanges of the valve. There are ports on both the side and the bottom of the valve, freely introducing steam and other hot medium to ensure valves stable operation under high pressure and temperature conditions. At the same time, optimization the layout of the steam flow channel guarantee the heat distribute equally and avoid local overheating or insufficient heating.

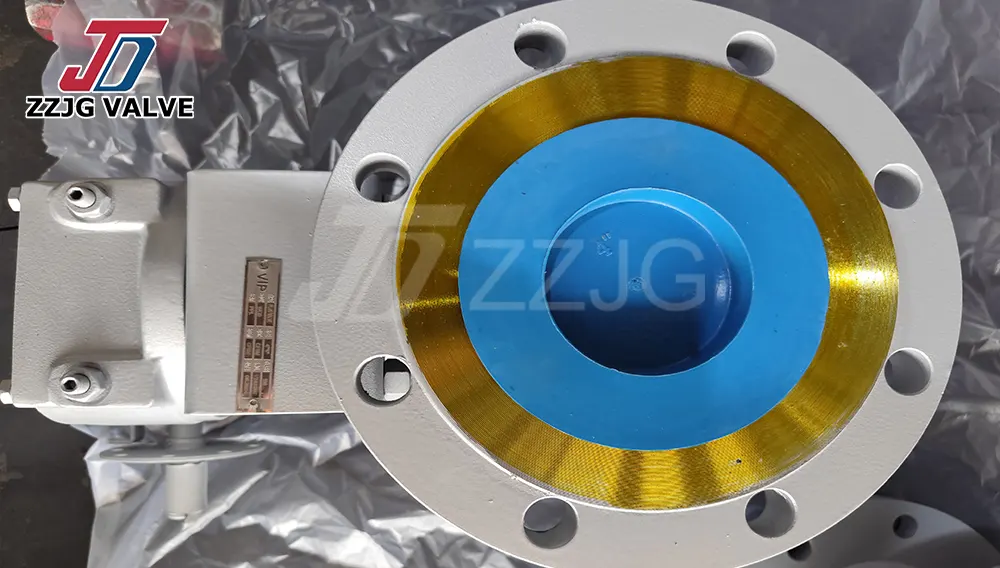

3.2 Sealing Technology

Sealing technology, advanced metal hard sealing and PTFE soft sealing solutions can be selected based on the characteristic of different media. For instance, in chemical industry, combination of 316L stainless steel and PTFE can used for corrosive media, while carbon steel and hard alloy sealing are more suitable for high-temperature asphalt transportations. Meanwhile, application of self-lubricating bearing design significantly reduce the rotational frictional resistance and extend the service life of valve.

3.3 Material Selection

In term of material selection, valve body usually made of WCB carbon steel, 304/316 stainless steel or special alloy steel adapting to different temperature and corrosive environment. In addition, modular design concept enable valve to flexible adapt to various drive devices such as manual, electric or pneumatic, provide convenience for industrial automation control. The core technologies jointly ensure the outstanding performance of the steam jacketed plug valve under harsh working condition.

4. Product Advantages

Comparing with conventional valves, steam jacketed plug valve have significant advantage in control of high-temperature media. It's anti-solidification design ensure smooth transportation of high-viscosity media through continuous heating, make it particularly suitable for pipeline system containing easy solidifying substances such as asphalt and heavy oil. In term of temperature resistance, selection of high-quality material and structural design enable the valve to withstand high-temperature steam environments above 400℃ for long time, meeting the strict requirements of industries such as petrochemical and power.

Sealing reliability is another highlight. It adopt sealing structure that complies with API and ANSI standard, with a extreme low leakage rate, effectively ensure production safety. In term of maintenance, application of modular design makes disassembly, cleaning and component replacement simple and fast, significant reduce maintenance costs. Additionally, plug valves can be equipped with temperature sensors and intelligent control system based on specific requirements to achieve precise temperature control and further enhance energy efficiency. The advantages make the steam jacketed plug valve a ideal choice for industries with strict hygiene requirements such as food processing and pharmaceuticals.

5. Application Areas

In the petrochemical industry, steam jacketed plug valves are widely used in the transportation systems of high-viscosity media such as asphalt, heavy oil, wax oil, and crude oil. Their excellent anti-solidification properties ensure the continuous and stable operation of production lines. In the temperature control system of chemical reaction vessels, such valves can precisely regulate the flow of heat media, ensuring the temperature stability of the reaction process.

The food processing industry also benefits from the excellent performance of this valve. In the pipeline transportation of easily solidifying foods such as chocolate, syrup, and edible oil, the continuous heating function of the steam jacket prevents the products from crystallizing or hardening inside the pipeline. In the high-temperature sterilization process, the high sealing performance and temperature resistance of the valves provide a reliable guarantee for food safety.

The pharmaceutical industry has extremely high requirements for equipment cleanliness. The hygienic design of the steam jacketed plug valve complies with GMP standards and is particularly suitable for heating and conveying systems of high-viscosity raw materials such as liquid medicines and colloids. In the energy and power sector, this type of valve is widely used in steam regulation of thermal pipelines and high-temperature medium control in boiler systems, and its durability and reliability have been verified by the industry.

6. Conclusion

With improving of the industrial automation, steam jacket plug valve is moving towards intelligence. In the future, Intelligent temperature control valve integrating temperature sensor and automatic control system will be a trend, by adjust heating power accurately, to achieve more efficient power use. In industries such as chemical engineering, food, and pharmaceuticals, we are more strict with these industries, the steam jacketed valve with anti-solidification, high-temperature resistance, intelligent control, etc will be applied more widely, providing more full solutions for industrial fluid control.

For enterprises that need to handle high-viscosity or easily solidifying media, choosing the appropriate steam jacketed plug valve is crucial for ensuring production continuity. It is recommended that users comprehensively consider the characteristics of the medium, temperature and pressure parameters, as well as automation requirements when selecting a model. If necessary, they should consult professional valve suppliers to obtain technical support to ensure the selection of the most suitable product model for the working conditions.

To better meet your needs, we offer a variety of specifications and customized services. The ZZJG VALVE professional team will promptly provide detailed information on product specifications, technical details, pricing, and after-sales service. We look forward to working with you to ensure the smooth implementation of your project!

Previous: Expanding Plug Valve Guide in Industrial Applications

Next: Application Of Thermal Insulation Jacketed Plug Valve In Low Temperature Environment In Winter