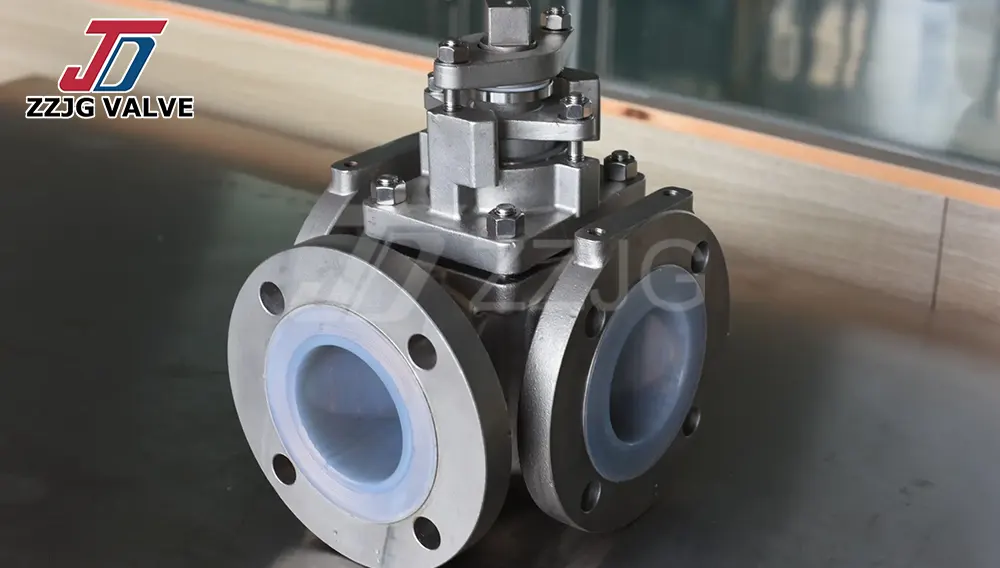

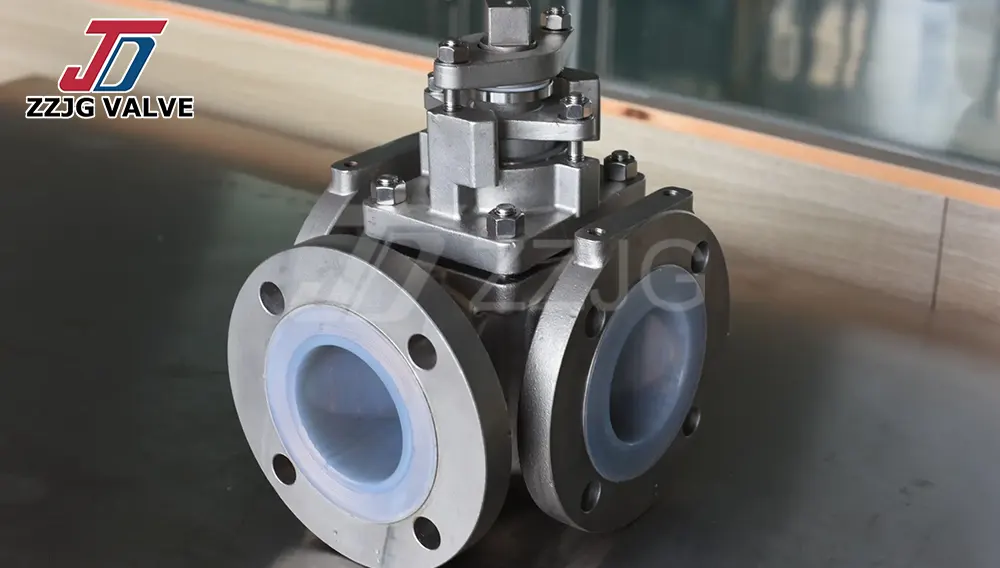

Three-Way Plug Valve: Where Is It Used the Most?

19 Jan, 2026

In the valve family, the three-way plug valve is a real"all-rounder": one handle controls three ports, and a 90°turn changes direction, splits flow, or shuts the pipeline. But where is it used most?

1. Petrochemicals

A Malaysia refinery transfer residue that is very thicker in winter. Common ball valves got stuck after a few turns, and workers had to warm them with steam. Switching to a jacketed three-way plug valve solved the issue. The rotating plug act like a razor, scrape oil off the sealing surface. The valve insulation design frees the pipeline from temperature constraints. It also eliminates the need for the extra steam, ensuring smooth medium flow.

Features:

- Sticky, easy-to-solidify fluids need the "self-cleaning" feature

- Frequent "one-in, two-out" tank switching or blending is done with a single valve

- Corrosion-resistant materials (Stainless Steel / PTFE lining) are available as an option. They are resistant to both acids and alkalis.

2. Oil & Gas Fields

At metering station in Saudi Arabia's Ghawar Oil Field, six oil wells need to individually weighed. Before, two gate valves and a bypass were used, but more valves meant a higher risk of leaks. To solve this, they switched into a single DN100, Class 600 oil-sealed three-way plug valve. A 90°lever moves, medium will flow from "well A" to "well B" with zero external leakage—no smell of natural gas in the air.

Features:

- Remote locations demand easy to maintenance and "one valve does it all" to cut leak paths

- Oil-seal design needs no frequent greasing, ideal for sandstorms and big temperature swings

- Available up to Class 2500, can be buried or skid-mounted

3.Power Plants

An Russia Sverdlovsk Oblast (Свердловская область), power plant switches between cold-water bypass and hot-water main during boiler start-up. The three big valves used to take 15 minutes. After that, they changed them to an electric three-way plug valve, now finishes the job in 3 seconds from the control room. Start-up time is half an hour shorter, saving more money and economize on manpower per year than the valve cost.

Features:

- High temp (200–550℃) and high pressure (PN16–PN100) call for metal-to-metal sealing plug valve

- Fast 90°change-over saves start-up/shut-down time

- One 3 way plug valve replaces three valves, give neat pipe layout and smaller insulation job

4. Pulp & Paper / Mining

A Finland mill bleaches pulp that looks like "gritty porridge". Stainless ball valves used before wore out after three months. After replacing it with a metal, stellite-faced three-way plug valve has run 18 months leak-free. During the shutdown and disassembly process, the valve core only be found minor scratches.

Features:

- Hard particles in pulp or slurry need "self-cleaning+ wear resistance"

- Short sealing path leaves no place for particles to hide, so wear is lower

- Sizes up to DN500 handle large flows

5. Food & Pharmacy

In Inner Mongolia, a dairy company conducts a "CIP" cleaning process every day - alternating between alkaline, acidic, and hot water for rinsing. Using a three-way ball valve, the three cleaning solutions are connected to the same inlet. The PLC controls the rotation sequence, ensuring there are no dead zones throughout the cleaning process. This is half the time-saving compared to manual pipe changes, and the microbial test is completed successfully each time.

Features:

- 316L stainless, pocket-free design meets FDA / GB 4806 hygiene rules

- Withstands on-line steam sterilisation (SIP) at 120–150℃

- PTFE or metal seals contain no lubricant, avoiding product contamination

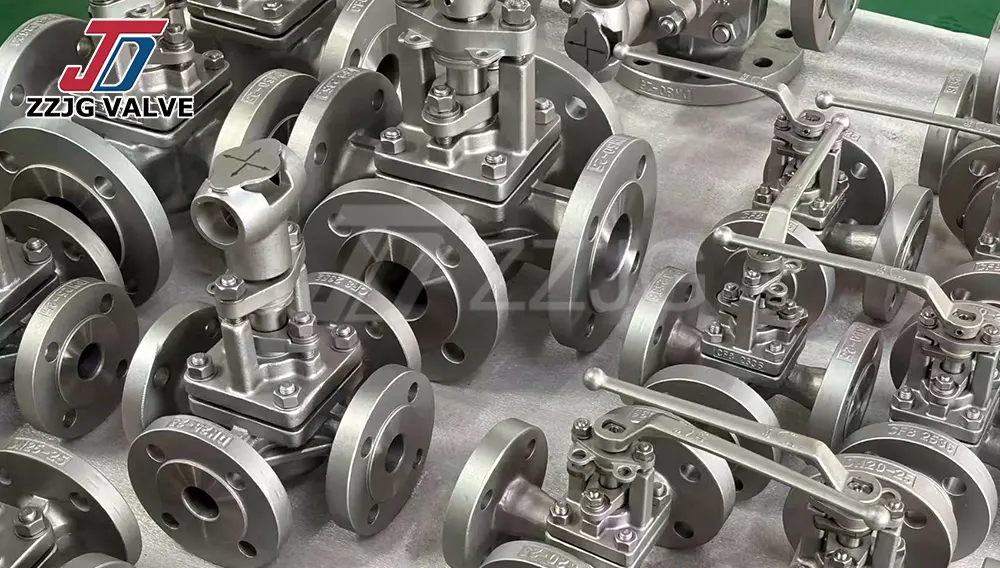

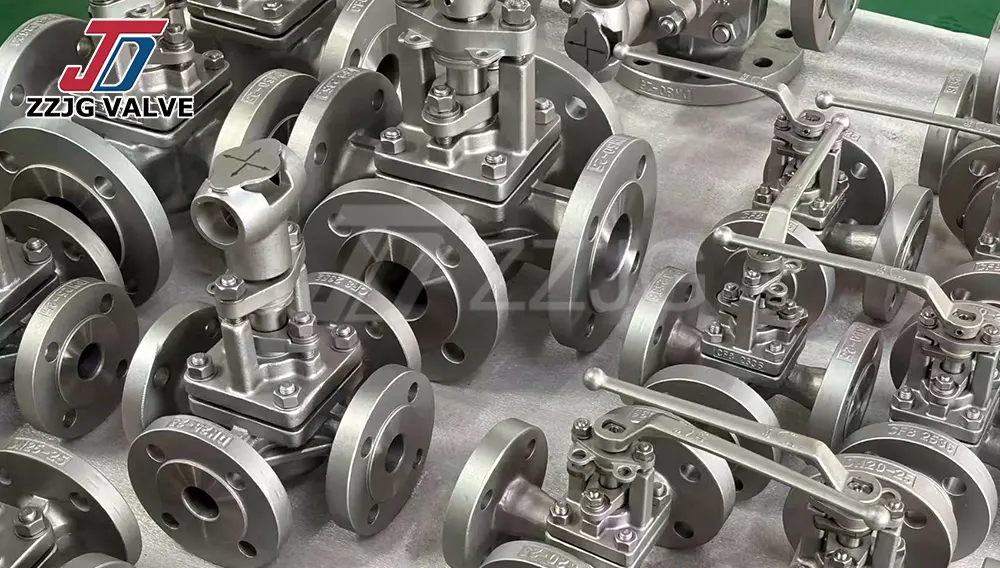

Quick "Top Users" List

1. Petrochemicals & oil-gas fields (biggest volume, toughest conditions)

2. Power, pulp & paper, mining (focused applications, one valve replaces many)

3. Food & pharmacy (highest hygiene demand, fastest growing)

If you want to learn more about 3 way plug valve, please contact ZZJG VALVE.

1. Petrochemicals

A Malaysia refinery transfer residue that is very thicker in winter. Common ball valves got stuck after a few turns, and workers had to warm them with steam. Switching to a jacketed three-way plug valve solved the issue. The rotating plug act like a razor, scrape oil off the sealing surface. The valve insulation design frees the pipeline from temperature constraints. It also eliminates the need for the extra steam, ensuring smooth medium flow.

Features:

- Sticky, easy-to-solidify fluids need the "self-cleaning" feature

- Frequent "one-in, two-out" tank switching or blending is done with a single valve

- Corrosion-resistant materials (Stainless Steel / PTFE lining) are available as an option. They are resistant to both acids and alkalis.

2. Oil & Gas Fields

At metering station in Saudi Arabia's Ghawar Oil Field, six oil wells need to individually weighed. Before, two gate valves and a bypass were used, but more valves meant a higher risk of leaks. To solve this, they switched into a single DN100, Class 600 oil-sealed three-way plug valve. A 90°lever moves, medium will flow from "well A" to "well B" with zero external leakage—no smell of natural gas in the air.

Features:

- Remote locations demand easy to maintenance and "one valve does it all" to cut leak paths

- Oil-seal design needs no frequent greasing, ideal for sandstorms and big temperature swings

- Available up to Class 2500, can be buried or skid-mounted

3.Power Plants

An Russia Sverdlovsk Oblast (Свердловская область), power plant switches between cold-water bypass and hot-water main during boiler start-up. The three big valves used to take 15 minutes. After that, they changed them to an electric three-way plug valve, now finishes the job in 3 seconds from the control room. Start-up time is half an hour shorter, saving more money and economize on manpower per year than the valve cost.

Features:

- High temp (200–550℃) and high pressure (PN16–PN100) call for metal-to-metal sealing plug valve

- Fast 90°change-over saves start-up/shut-down time

- One 3 way plug valve replaces three valves, give neat pipe layout and smaller insulation job

4. Pulp & Paper / Mining

A Finland mill bleaches pulp that looks like "gritty porridge". Stainless ball valves used before wore out after three months. After replacing it with a metal, stellite-faced three-way plug valve has run 18 months leak-free. During the shutdown and disassembly process, the valve core only be found minor scratches.

Features:

- Hard particles in pulp or slurry need "self-cleaning+ wear resistance"

- Short sealing path leaves no place for particles to hide, so wear is lower

- Sizes up to DN500 handle large flows

5. Food & Pharmacy

In Inner Mongolia, a dairy company conducts a "CIP" cleaning process every day - alternating between alkaline, acidic, and hot water for rinsing. Using a three-way ball valve, the three cleaning solutions are connected to the same inlet. The PLC controls the rotation sequence, ensuring there are no dead zones throughout the cleaning process. This is half the time-saving compared to manual pipe changes, and the microbial test is completed successfully each time.

Features:

- 316L stainless, pocket-free design meets FDA / GB 4806 hygiene rules

- Withstands on-line steam sterilisation (SIP) at 120–150℃

- PTFE or metal seals contain no lubricant, avoiding product contamination

Quick "Top Users" List

1. Petrochemicals & oil-gas fields (biggest volume, toughest conditions)

2. Power, pulp & paper, mining (focused applications, one valve replaces many)

3. Food & pharmacy (highest hygiene demand, fastest growing)

If you want to learn more about 3 way plug valve, please contact ZZJG VALVE.

Previous: Stainless Steel Plug Valves Advantages

Next: Back to list