Expanding Plug Valve Guide in Industrial Applications

ZZJG Valve provides the above information on expanding plug valve guide in industrial applications. If you want to know more about plug valve guide, please contact us via WhatsApp or email.

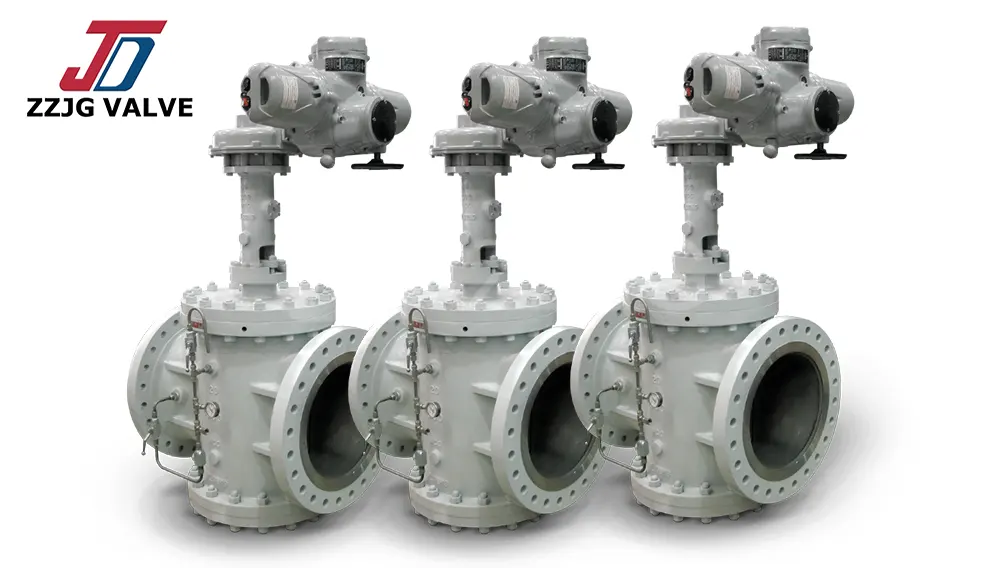

In the complex world of industrial fluid control, the expanding plug valve has emerged as a reliable and efficient solution for various operations. From oil and gas pipelines to chemical processing plants, this valve type offers unique advantages that make it a preferred choice for many engineers and plant managers. Let's dive into what makes expanding plug valves stand out, how they work, and where they excel.

How Does an Expanding Plug Valve Work?

At its core, an expanding plug valve operates on a simple yet effective principle. The valve consists of a body, a plug (or core), and an actuating mechanism. The plug is designed to expand or contract within the valve body, creating a tight seal when closed and allowing smooth flow when open.

When the valve is in the closed position, the plug expands to press against the valve seat, preventing any fluid from passing through. This expansion is typically achieved through a mechanical mechanism, often involving a stem that drives the plug's movement. When the valve needs to open, the plug contracts, creating a gap between the plug and the seat, enabling fluid to flow freely through the valve.

This ensures a secure seal even in high-pressure and high-temperature environments, making it suitable for demanding industrial settings.

Expanding plug valves offer several benefits that set them apart from other valve types:

Superior Sealing: The expanding plug design ensures a tight seal, minimizing leakage even with viscous or abrasive fluids.

Durability: Constructed from robust materials like stainless steel, cast iron, or special alloys, these valves withstand harsh conditions and have a long service life.

Low Maintenance: With fewer moving parts compared to some other valves, expanding plug valves require less frequent maintenance, reducing downtime.

Versatility: They work well with various fluids, including liquids, gases, and slurries, making them suitable for diverse industries.

Expanding plug valves find use in a wide range of industries:

Oil and Gas: Used in pipelines for controlling the flow of crude oil, natural gas, and refined products.

Chemical Processing: Ideal for handling corrosive chemicals due to their strong sealing properties and material options.

Water Treatment: Effective in managing the flow of water and wastewater, where tight seals are crucial to prevent contamination.

Power Generation: Employed in power plants to control steam and other fluids in energy production processes. Factors to Consider When Choosing an Expanding Plug Valve

Selecting the right expanding plug valve for your application involves considering several factors:

Fluid Type: The nature of the fluid (corrosive, abrasive, viscous) determines the material of the valve.

Pressure and Temperature: Ensure the valve can handle the operating pressure and temperature of your system.

Size: Choose the appropriate valve size based on the pipeline diameter and flow requirements.

Actuation Type: Decide between manual, pneumatic, hydraulic, or electric actuation based on automation needs and operational convenience.

Installation and Maintenance Tips

Proper installation and maintenance are essential for optimal performance of expanding plug valves:

Installation: Follow the manufacturer's guidelines for correct installation, ensuring proper alignment with the pipeline and secure connections.

Regular Inspection: Check for signs of wear, leakage, or damage periodically. Clean the valve and lubricate moving parts as recommended.

Repair: Address any issues promptly. Replace worn components with genuine parts to maintain the valve's integrity.

Expanding plug valves are a valuable asset in industrial fluid control systems, offering reliable performance, durability, and versatility. By understanding their working principle, advantages, applications, and proper selection and maintenance procedures, you can make informed decisions to ensure efficient operation in your facility. Whether you’re working in oil and gas, chemical processing, or water treatment, an expanding plug valve could be the solution you need for precise and reliable fluid control.

Previous: Indonesian customers visited ZZJG VALVE company

Next: Steam Jacketed Plug Valve: Efficient and Durable Fluid Control Solution