Lubricated vs Non-Lubricated Plug Valves for Saudi Market

In industries such as petroleum, natural gas, chemical engineering and water treatment, Plug valves are widely used due to their excellent sealing performance and fluid control capabilities. In an energy-intensive market like Saudi Arabia, choosing the right type of plug valve is of vital importance, especially in high-temperature, high-pressure and corrosive medium environments. Plug valves are mainly divided into two types: Lubricated (Lubricated Plug Valve) and Non-Lubricated (non-Lubricated Plug Valve), and they have significant differences in structure, performance and maintenance. This article will delve into the differences between these two types of valves and analyze their applicable scenarios in the Saudi market.

1.Lubricated Plug Valve

1.1 Structure and Working Principle

Core features of the lubricated plug valve is it internal lubrication system. There is one lubricant injection channel inside the valve. Before operation or at regular interval, special grease (such as silicon-based, petroleum-based lubricants) is injected between the valve seat and the plug to reduce friction and enhance sealing performance.

1.2 Main Advantages

- Excellent sealing performance: The lubricant fills the tiny gap between the cock and the valve body, effectively preventing leakage and making it suitable for high-pressure working conditions.

- Reduce wear: Lubricants lower direct friction between metals, extending the service life of valves.

- Adaptable to harsh working conditions: Suitable for media containing particulate matter, high viscosity or prone to crystallization, such as crude oil, mud, etc.

1.3 Applicable Scenarios (Saudi Market)

The oil and gas industry in Saudi Arabia has extremely high requirements for valves. Lubricated plug valves perform outstandingly in the following scenarios.

- Crude oil transportation pipelines: High-sulfur crude oil is prone to corroding valves. Lubricants can provide additional protection.

- Oil refinery: In high-temperature and high-pressure environments, lubricated valves can maintain stable sealing.

- Seawater desalination plant: Lubricants can reduce the wear of valves caused by salt crystallization.

1.4 Maintenance Requirements need to be replenished with lubricant regularly; otherwise, it may lead to seal failure or jamming. In the high-temperature environment of Saudi Arabia, lubricants may evaporate quickly, so it is necessary to choose high-temperature resistant grease and enhance maintenance.

need to be replenished with lubricant regularly; otherwise, it may lead to seal failure or jamming. In the high-temperature environment of Saudi Arabia, lubricants may evaporate quickly, so it is necessary to choose high-temperature resistant grease and enhance maintenance.

2. Non-Lubricated Plug Valve

2.1 Structure and Working Principle

Non-lubricating plug valves use special designs (such as elastic bushings or polymer coatings) to replace the lubrication system, achieving sealing by taking advantage of the inherent elasticity and low friction properties of the material, without the need for additional lubrication.

2.2 Main Advantages

- Maintenance-free: No need to add lubricants regularly, reducing operation and maintenance costs.

- Strong corrosion resistance: Made of PTFE (polytetrafluoroethylene) or other chemically resistant materials, it is suitable for corrosive media such as acids and alkalis.

- Quick opening and closing: With a low coefficient of friction, it is easier to operate and suitable for applications that require frequent opening and closing.

2.3 Applicable Scenarios (Saudi Market)

In Saudi Arabia, non-lubricating plug valves are widely used in the following fields:

- Chemical industry: Handling strong acids, strong bases or organic solvents, such as the chemical plants of Saudi Basic Industries Corporation (SABIC).

- Natural gas transportation: Dry natural gas does not require lubrication, and non-lubricated valves can prevent contamination.

- Water treatment system: Municipal water supply or sewage treatment, reducing maintenance requirements.

2.4 Limitations

- Not suitable for high-particle media: Hard particles may damage the elastic sealing material.

- Temperature limitation: The high-temperature resistance of materials such as PTFE is limited (usually ≤200°C), and they are not suitable for ultra-high-temperature working conditions.

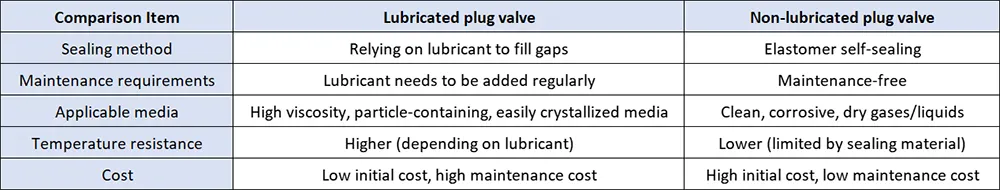

3. Lubricated vs. Non-lubricated Plug Valves: Key Comparison

4. Suggestions for market selection in Saudi Arabia

The industrial environment in Saudi Arabia is diverse. When selecting valves, the characteristics of the medium, working conditions and maintenance capabilities should be comprehensively considered

(1) Oil and gas industry: Lubricated plug valves are preferred, especially when handling sulfur-containing crude oil or high-pressure pipelines.

(2) Chemical industry and sewage treatment: Non-lubricating valves are more suitable for corrosive media and maintenance-free requirements scenarios.

(3) High-temperature applications: If the temperature exceeds 200°C, lubricated valves are more reliable, but high-temperature resistant lubricants must be selected.

5. Conclusion

Lubricated and non-lubricated plug valves each have their own advantages. The application in the Saudi market should be selected based on specific working conditions. Lubricated valves are suitable for high-pressure and high-wear environments, but they have higher maintenance requirements. Non-lubricating valves are more suitable for corrosive media and applications with low maintenance requirements. With the continuous development of Saudi Arabia's industry, the demand for efficient and durable valves will keep increasing. Correct selection can significantly enhance system reliability and economic benefits.

If you want to know more about PLUG valves or make inquiries, welcome to contact ZZJG PLUG VALVE. We have a professional technical team to serve you.

Previous: PTFE and PFA Lined Plug Valves for Extreme Conditions

Next: Application of Plug Valves in water Treatment in the Middle East