Application of Plug Valves in water Treatment in the Middle East

In the Middle East, due to the arid climate and scarcity of fresh water resources, seawater desalination and sewage treatment technologies have become the key to ensuring water supply. As an important component of the water treatment system, Plug Valve is widely used in seawater desalination plants, sewage treatment facilities and industrial water treatment projects due to its excellent sealing performance, corrosion resistance and efficient fluid control ability. This article will focus on discussing the application cases of plug valves in the water treatment industry in the Middle East and analyze their advantages in seawater desalination and sewage treatment systems in regions such as Dubai.

1. Application Cases Of Plug Valves In Seawater Desalination Plants

(1) Plug Valve for Water Treatment Dubai Desalination Project, United Arab Emirates

Dubai is one of the regions in the world that leads in seawater desalination technology. Its large-scale reverse osmosis (RO) and multi-stage flash (MSF) seawater desalination plants widely use plug valves.

- Application scenario: A large-scale seawater desalination plant adopts seawater reverse osmosis (SWRO) technology, with a daily fresh water output of 100,000 cubic meters. The seawater in the system needs to be pressurized to 60-80 bar (870-1160 psi) by a high-pressure pump before it can pass through the reverse osmosis membrane.

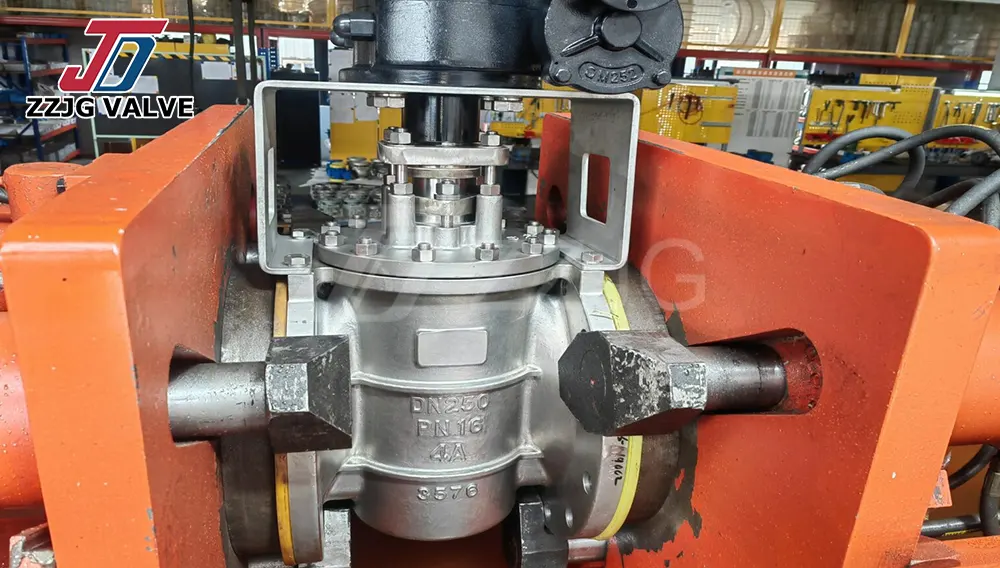

- Application situation: The project party selected the ANSI Class 600 grade high-pressure plug valve for flow control at the outlet of the high-pressure pump and the energy recovery device.

- Application effect: After using the plug valve, there is no leakage in the system under high-pressure operation conditions, significantly enhancing the operational reliability of the equipment. The precise regulation capability of the plug valve has increased the efficiency of the energy recovery device by approximately 5%, effectively reducing the overall energy consumption. The selection of highly corrosion-resistant materials has extended the service life by more than 30% compared to traditional ball valves, reducing the cost of frequent valve replacement.

(2) The Desalination Project Of The Red Sea In Saudi Arabia

- Application scenario: A 100,000-ton seawater desalination plant in Saudi Arabia. The seawater desalination process requires continuous and stable operation, and seawater is highly corrosive. Therefore, the corrosion resistance of valves has become the main consideration.

- Application situation: The valve body of the plug valve selected by this factory is made of super duplex steel (SS2750).

- Application effect: The plug valve's features such as low flow regulation, low fluid resistance, simple structure for easy maintenance, good sealing performance, and no restrictions on installation direction have made it perform outstandingly in the seawater desalination process of this factory, meeting the process requirements and ensuring the stable operation of the system.

2. Application Cases Of Plug Valves In Sewage Treatment Plants

(1) ABU Dhabi Municipal Wastewater Treatment Plant

During the sewage treatment process, a large amount of sludge is produced. The transportation and treatment of sludge require reliable valves for control.

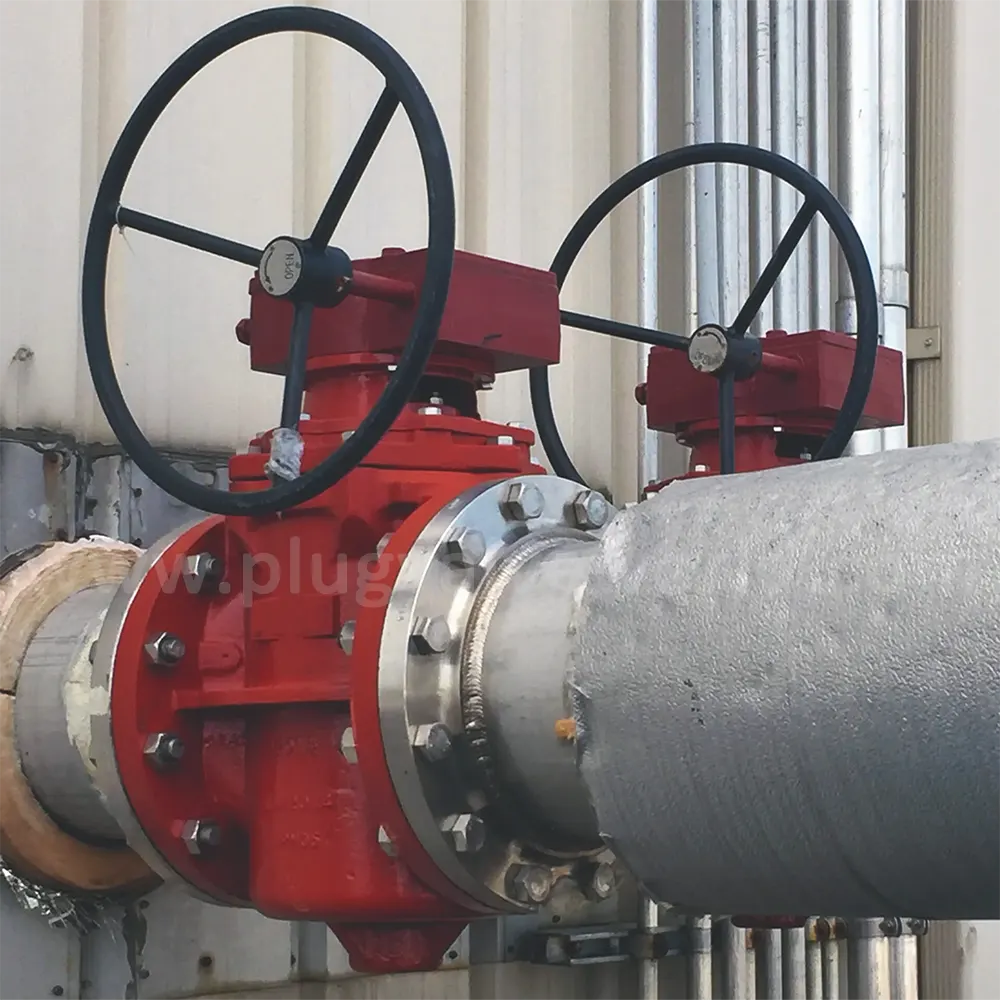

A certain sewage treatment plant installed an eccentric plug valve on the sludge pipeline to control the flow of sludge. The valve body of this plug valve is made of wear-resistant material, and the valve seat is made of elastic material, which can effectively prevent the wear and blockage of the valve by solid particles in the sludge.

After using the eccentric plug valve, the operation of the sludge pipeline became more stable, the sealing performance of the valve was good, and no leakage occurred. Meanwhile, due to the simple operation and convenient maintenance of the plug valve, maintenance costs and downtime are reduced

(2) Industrial Wastewater Treatment Project In Doha, Qatar

During the sewage treatment process, various chemical agents such as flocculants and disinfectants need to be added to enhance the treatment effect.

A certain sewage treatment plant installed PFA plug valves on the chemical agent dosing pipeline. The PFA plug valve has excellent corrosion resistance and can withstand the erosion of chemical agents. Meanwhile, it has good sealing performance and can precisely control the dosage of chemicals.

After using the PFA plug valve, the addition of chemical agents becomes more precise, avoiding the problem of agent waste and poor treatment effect caused by valve leakage or blockage. Meanwhile, the PFA plug valve has a long service life, reducing the frequency of valve replacement and lowering maintenance costs

3.Why Are Plug Valves The Best Choice For Water Treatment In The Middle East?

Plug valves are regarded as one of the best choices in the field of water treatment (especially seawater desalination) in the Middle East, mainly for the following reasons:

(1)Strong corrosion resistance

- Material advantages: Desalination plants in the Middle East are facing the problem “high salinity” and “high corrosion resistance” in the seawater environment. Plug valves usually adopt high performance corrosion-resistant material, such as super duplex steel, titanium alloy, Hastelloy, etc.These material are able to resist chloridion corrosion in seawater, avoiding the problems like pitting, crevice corrosion, and extend the service life of the valve.

(2)Precise flow control

- Flexibility of operation: During the sea water desalination, whether it is reverse osmosis(RO) system or Multi-stage flash distillation(MSF), Multi-effect Distillation(MED) system, they all need accurate control of the speed and pressure of the water flow. Because of the unique design, plug valve is able to achieve fast and accurate flow regulation, which is important to dilution process and system efficiency.

- Energy-saving effect: In a reverse osmosis system, the energy consumption of high-pressure pump is one of its main costs. Plug valve is able to control high pressure water flow, reduce unnecessary energy loss, thus reducing the operation cost.

(3)High sealing performance

- Sealing technology: The plug valve adopts advanced sealing technology. These designs ensure the sealing performance of the valves under high pressure and vacuum conditions, prevent seawater leakage, and guarantee the safe operation of the system.

- Low maintenance cost: The high sealing performance reduces the maintenance frequency caused by leakage, lowering maintenance costs and downtime.

(4)Adapt to harsh environments

- Environmental tolerance: The climate in the Middle East is hot, and seawater desalination plants are usually located along the coast or at sea, with extremely harsh environmental conditions. The design of the plug valve can adapt to environments with high temperatures, high humidity and high salinity. For instance, some plug valves have adopted special coatings and protective measures, further enhancing their durability in harsh environments.

(5)Easy to maintain and operate

- Maintenance convenience: The daily maintenance of seawater desalination plants is of vital importance. The design of plug valves is usually convenient for disassembly, cleaning and maintenance. Its simple structure make the maintainer change the seal components or carry out other necessary maintenance work, thereby lowering the downtime.

- Ease of operation: Plug Valve is easy to cooperate, by rotating the lever and electric actuator, the valve can achieve opening and closing swiftly and flow regulation. This easy operation method is helpful to improve operational efficiency and reduce human errors.

(6)Economy

Cost-effectiveness: Although high-performance plug valves may have a slightly higher initial investment than some traditional valves, their long service life, low maintenance costs, and energy-saving effects result in a lower total cost of ownership (TCO). For instance, the use of corrosion-resistant materials for plug valves can reduce the frequent replacement caused by corrosion, thereby lowering long-term operating costs.

4.Conclusion

Plug valves, with their outstanding corrosion resistance, high-pressure adaptability and long service life, have become the best valve choice for seawater desalination and sewage treatment projects in the Middle East. Whether it is the RO seawater desalination plant in Dubai or the thermal desalination system in Saudi Arabia, plug valves play a crucial role in ensuring efficient and stable operation. In the future, with the popularization of intelligent water treatment technology, the application of plug valves will further expand, helping the Middle East achieve sustainable water resource management.

Previous: Lubricated vs Non-Lubricated Plug Valves for Saudi Market

Next: Where to Buy Quality Plug Valves: Your Ultimate Supplier Checklist for 2025