Corrosion-Resistant 2205 Duplex Steel Plug Valve

09 Feb, 2026

1. Introduction

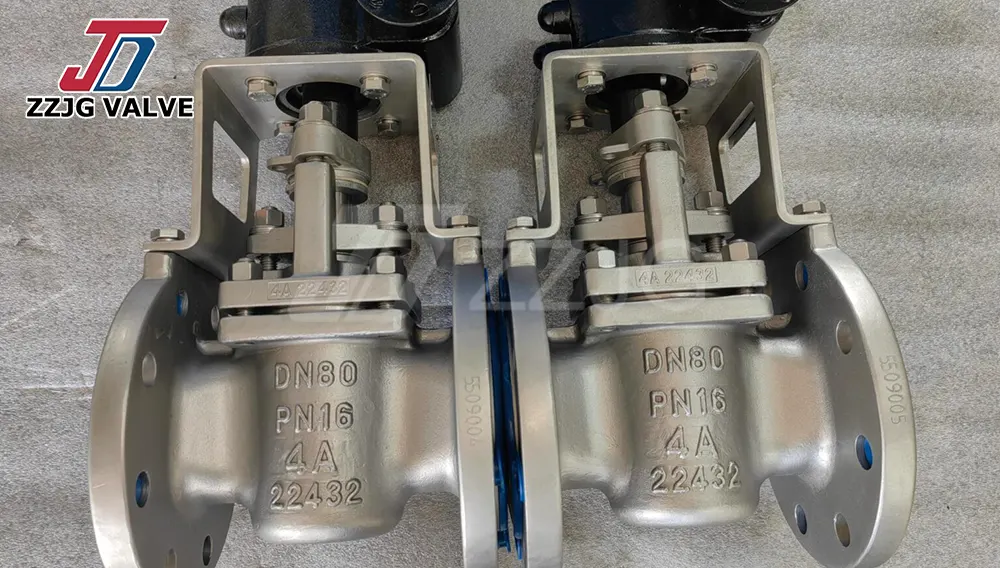

2205 Duplex Steel Plug Valve. The product is made of 2205 duplex stainless steel (UNS S31803/S32205) , with a strength nearly twice that of ordinary stainless steel, and resistant to salt water and acid corrosion. The valve body is of a plug structure, and can be opened and closed by rotating 90 degrees, without any stagnant dead corners, and make it suitable for fluid containing particles.

The 2205 duplex stainless steel plug valve has an aperture range from DN15 ~ DN1600, with pressure ratings from Class150 to Class1500. Sealing options are either soft seal or metal seal. The applicable temperature range is from -40℃ to 300℃. The new product has passed salt spray and high-pressure sealing tests and is plan for use in seawater desalination, chemical industries, and offshore platforms. Currently, the valves are available for orders and the delivery period is approximately four weeks.

2. Applications

* Coastal factorys, seawater desalination plants - Extract seawater and discharge concentrated brine, not prone to rust.

* Chemical plants - Process acids and bases, ordinary steel is quickly corroded, but it can withstand it.

* Oil platforms - Salt water and oil gas flow together, high strength and it won't be bitten through by chloride ions.

* Paper mills - Black liquid and green liquid are hot and corrosive, using it to switch pipelines can extend their lifespan.

* Power plant desulfurization - Desulfurization slurry contains particles, 4A plug valve comes with a "scraping blade", less likely to get stuck.

* New energy sources - Hydrogen, photovoltaic cooling fluid, high pressure can also seal it.

3. Can It Work In Extreme Temperatures?

As long as there is troublesome media such as "salt water, acid solution, particles, high pressure", it can be considered.

Its most comfortable temperature range is from -46 ℃ to 300 ℃.

When the temperature is lower than -46 ℃, the material will become brittle and easy to cracking;

When temperature is more high than 300 ℃, the internal structure will deteriorate, and the strength and corrosion resistance will both decrease.

Therefore, for true extreme cold (liquefied natural gas -162 ℃) or extreme heat (steam 500 ℃) conditions, other materials should be selected instead of 2205.

Previous: Three-Way Plug Valve: Where Is It Used the Most?

Next: Back to list