How To Choose The Appropriate Paint For a Plug Valve?

29 Oct, 2025

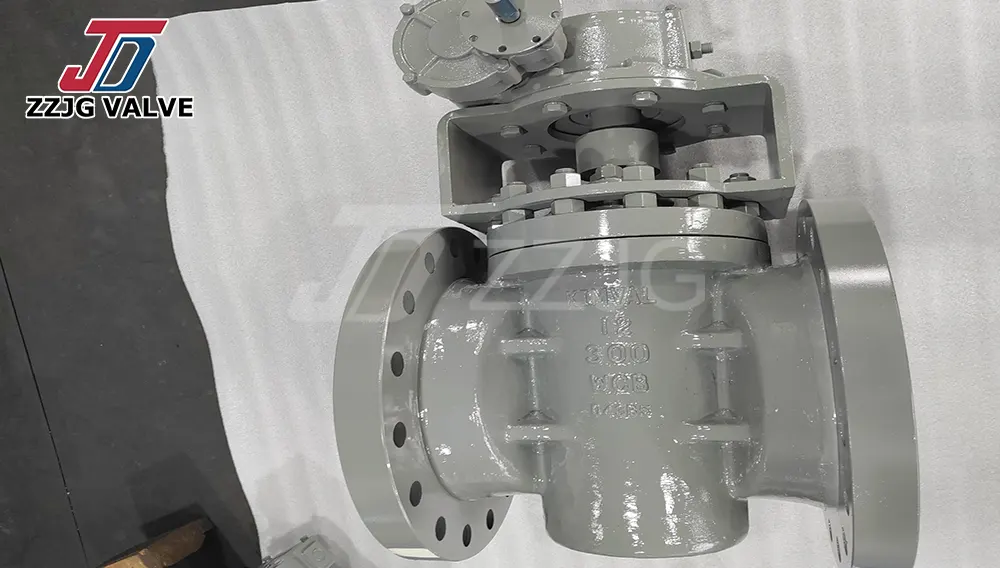

Painting the plug valve is similar to painting metal doors or outdoor furniture. The purpose is to prevent rusting and aging, making it more durable. Choosing the right paint depends on four key factors: the material of the plug valve itself, the intended use, the severity of corrosion, and whether there are any environmental regulations.

1. Consider The Material Of Plug Valve

Different materials require different primers to ensure a firm bond and prevent rusting.

For ordinary steel plug valves (the ones most prone to rust):

Use zinc-rich primer. It has extremely strong anti-rust properties. This primer contains a large amount of zinc powder, which will "sacrifice itself" before the iron rusts to resist corrosion. It's like the protective armor for the plug valve, making it an ideal choice for corrosive environments.

For stainless steel or alloy steel valves (which are not prone to rust themselves):

To enhance protection and appearance, you can choose a product called "Light Metal Epoxy Primer". Its greatest advantage is that it usually doesn't require sandblasting and can be applied directly with a brush, resulting in a strong adhesion and a mild, environmentally friendly, and low-odor coating.

2. Key Step: Consider The Intended Use Of The Valve.

The environment determines the appropriate combination of paints.

For indoor dry areas (such as ordinary factories):

For applications with low requirements, the cost-effective "epoxy primer + epoxy topcoat" combination can meet the needs and provide sufficient rust protection.

For outdoor use, exposed to sunlight and rain:

These requirements are even higher for the paint. It needs to be rust-proof and also resistant to sun exposure and rain. A classic combination is recommended: use "epoxy zinc-rich primer" as the base coat, "epoxy iron-based intermediate" as the thickening and reinforcing agent, and "acrylic polyurethane topcoat" as the outermost protective layer. The "topcoat" in this combination is like sunscreen and raincoat, able to maintain color and luster for a long time.

For coastal or offshore (highly corrosive) environments:

The salt and moisture in the coastal areas are extremely corrosive, requiring an enhanced coating system. We recommend "inorganic zinc-rich primer" + "epoxy ferrozine intermediate" + "epoxy topcoat". This combination complies with strict international anti-corrosion standards and is specifically designed for these harsh environments.

For chemical plants that may come into contact with acids and alkalis:

In such cases, a chemical-resistant coating is required. We recommend using epoxy phenolic varnish. It is like the protective suit for valves, effectively resisting corrosion from acids, alkalis and other liquids.

For high-temperature pipelines (such as those exceeding 150℃):

Ordinary coatings will melt and change color during the baking process, requiring the use of specialized "high-temperature resistant coatings". These coatings can firmly adhere to the plug valve surface even at high temperatures, preventing peeling or discoloration.

3. Other Techniques

Cleaning the surface: To achieve a good coating effect, the plug valve surface must be cleaned. Most high-performance coatings require sandblasting treatment to achieve a rough frosted glass effect. However, the mentioned stainless steel primer can conveniently be omitted in this step.

Environmental requirements: If your factory values environmental protection and worker health, please prioritize water-based industrial coatings or low-VOC (low harmful odor) products.

Reference standards: There are its own standards in the professional field. If you want to know more, you can refer to national standards, such as "Technical Conditions for Industrial Valve Coatings", which provides more detailed regulations.

4. "One-Stop" Recommendation

If you are unsure which one to choose, or if your plug valve will be used in a typical outdoor environment, the following solution is almost foolproof:

Undercoat: Epoxy zinc-rich undercoat (thickness approximately that of a human hair)

Intermediate coat: Epoxy mica iron ore paint (thickness can be increased for better protection effect)

Topcoat: Acrylic polyurethane topcoat (one layer is sufficient to achieve a beautiful and weather-resistant surface effect)

This combination features outstanding anti-corrosion properties, strong weather resistance and an attractive appearance, which can meet most requirements.

Choosing paint for a plug valve is like prescribing medicine. First, understand the "constitution" (material) and "operating environment" (location and corrosive conditions) of the plug valve. Then, select the appropriate "base coat", "intermediate coat" and "top coat" to ensure the long lifespan of the plug valve and a beautiful surface effect.

1. Consider The Material Of Plug Valve

Different materials require different primers to ensure a firm bond and prevent rusting.

For ordinary steel plug valves (the ones most prone to rust):

Use zinc-rich primer. It has extremely strong anti-rust properties. This primer contains a large amount of zinc powder, which will "sacrifice itself" before the iron rusts to resist corrosion. It's like the protective armor for the plug valve, making it an ideal choice for corrosive environments.

For stainless steel or alloy steel valves (which are not prone to rust themselves):

To enhance protection and appearance, you can choose a product called "Light Metal Epoxy Primer". Its greatest advantage is that it usually doesn't require sandblasting and can be applied directly with a brush, resulting in a strong adhesion and a mild, environmentally friendly, and low-odor coating.

2. Key Step: Consider The Intended Use Of The Valve.

The environment determines the appropriate combination of paints.

For indoor dry areas (such as ordinary factories):

For applications with low requirements, the cost-effective "epoxy primer + epoxy topcoat" combination can meet the needs and provide sufficient rust protection.

For outdoor use, exposed to sunlight and rain:

These requirements are even higher for the paint. It needs to be rust-proof and also resistant to sun exposure and rain. A classic combination is recommended: use "epoxy zinc-rich primer" as the base coat, "epoxy iron-based intermediate" as the thickening and reinforcing agent, and "acrylic polyurethane topcoat" as the outermost protective layer. The "topcoat" in this combination is like sunscreen and raincoat, able to maintain color and luster for a long time.

For coastal or offshore (highly corrosive) environments:

The salt and moisture in the coastal areas are extremely corrosive, requiring an enhanced coating system. We recommend "inorganic zinc-rich primer" + "epoxy ferrozine intermediate" + "epoxy topcoat". This combination complies with strict international anti-corrosion standards and is specifically designed for these harsh environments.

For chemical plants that may come into contact with acids and alkalis:

In such cases, a chemical-resistant coating is required. We recommend using epoxy phenolic varnish. It is like the protective suit for valves, effectively resisting corrosion from acids, alkalis and other liquids.

For high-temperature pipelines (such as those exceeding 150℃):

Ordinary coatings will melt and change color during the baking process, requiring the use of specialized "high-temperature resistant coatings". These coatings can firmly adhere to the plug valve surface even at high temperatures, preventing peeling or discoloration.

3. Other Techniques

Cleaning the surface: To achieve a good coating effect, the plug valve surface must be cleaned. Most high-performance coatings require sandblasting treatment to achieve a rough frosted glass effect. However, the mentioned stainless steel primer can conveniently be omitted in this step.

Environmental requirements: If your factory values environmental protection and worker health, please prioritize water-based industrial coatings or low-VOC (low harmful odor) products.

Reference standards: There are its own standards in the professional field. If you want to know more, you can refer to national standards, such as "Technical Conditions for Industrial Valve Coatings", which provides more detailed regulations.

4. "One-Stop" Recommendation

If you are unsure which one to choose, or if your plug valve will be used in a typical outdoor environment, the following solution is almost foolproof:

Undercoat: Epoxy zinc-rich undercoat (thickness approximately that of a human hair)

Intermediate coat: Epoxy mica iron ore paint (thickness can be increased for better protection effect)

Topcoat: Acrylic polyurethane topcoat (one layer is sufficient to achieve a beautiful and weather-resistant surface effect)

This combination features outstanding anti-corrosion properties, strong weather resistance and an attractive appearance, which can meet most requirements.

Choosing paint for a plug valve is like prescribing medicine. First, understand the "constitution" (material) and "operating environment" (location and corrosive conditions) of the plug valve. Then, select the appropriate "base coat", "intermediate coat" and "top coat" to ensure the long lifespan of the plug valve and a beautiful surface effect.

Previous: Key Factors for Selecting Lined Plug Valve vs. Soft Seated Plug Valve