Key Factors for Selecting Lined Plug Valve vs. Soft Seated Plug Valve

24 Oct, 2025

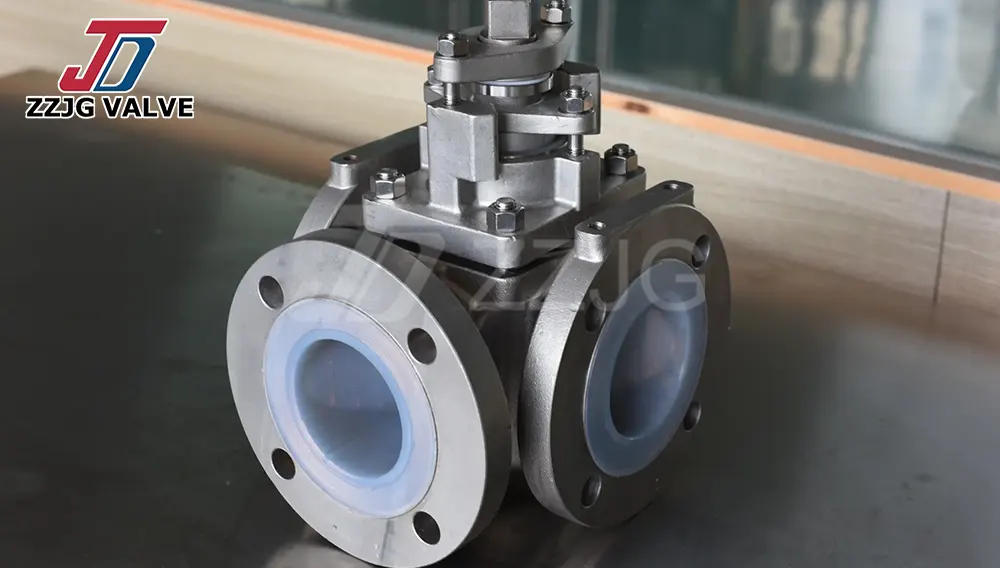

In actual selection, fluorine-lined plug valves and soft-sealed plug valves each have their own focuses. Users need to make a judgment based on specific working conditions.

1. Observe the strength of corrosiveness

If the oxidizability of the medium exceeds the corrosion resistance limit of conventional stainless steel (for example, concentrated sulfuric acid contains chloride ions or dry chlorine gas), a fully lined fluorine-lined plug valve must be selected to achieve "absolute anti-corrosion". If it is only a weak acid, weak base or ordinary aqueous solution, a soft-sealed plug valve can meet the requirements and is more cost-effective.

2. Check whether the medium contains solid particles

When the solid content in the medium is greater than 1% and the particle hardness is relatively high, the soft-sealed plug valve has better wear resistance due to its self-cleaning groove and elastic bushing. However, fully fluorine-lined valve seats are prone to being scratched by hard particles. In such cases, it is advisable to consider switching to a hard alloy valve core or reducing the frequency of use.

3. Check the temperature and pressure

Fluorine-lined plug valve: The upper limit of the long-term operating temperature is generally 150℃, and it can reach 180℃ in the short term.

Soft-sealed plug valve: Depending on the material of the bushing, it can cover a wide range from -196℃ (cryogenic conditions) to 300℃ (high-temperature type), but the pressure usually does not exceed PN25.

If both high temperature and high pressure are faced simultaneously, it is necessary to evaluate whether to choose metal seals or special reinforcing structures.

4. Check the purity requirements of the medium

In industries such as electronics and pharmaceuticals, where the precipitation of metal ions is required to be extremely low, fully lined fluorine-lined plug valves must be selected. If there are no strict requirements for ion precipitation in food-grade working conditions, food-grade soft-sealed plug valves can be selected to reduce operating torque and equipment costs.

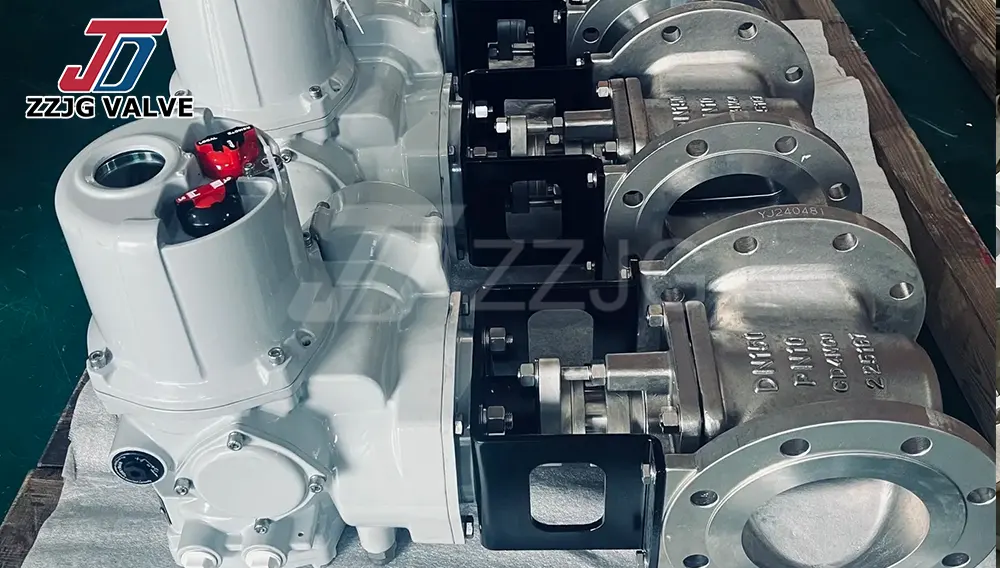

5. Check the operating frequency of the valve

For applications that require frequent opening and closing (such as more than 500 times a day), soft-sealed plug valves can significantly extend the service life of the actuator due to their low friction coefficient and small operating torque. If the medium is highly corrosive but the operation is not frequent, the fluorine-lined plug valve is more economical.

Fluorine-lined plug valves and soft-sealed plug valves are like "special forces" and "all-rounders" in the process industry. The former is known for its "absolute corrosion resistance", while the latter excels in "elastic sealing and wear resistance". In actual engineering, there is no fixed answer to which type of valve to choose. It must be comprehensively weighed based on factors such as the corrosiveness of the medium, solid content, temperature and pressure, purity requirements, and operating frequency. In critical application scenarios, it is even necessary to verify through fluid mechanics simulation and life calculation to ensure the achievement of the operation goals of safety, long cycle and low maintenance.

With the continuous advancement of fluoroplastic modification technology and elastomer composite materials, the performance boundaries of these two types of valves are still constantly expanding. In the future, in emerging fields such as new energy, seawater desalination and hydrogen energy, they will surely demonstrate greater application potential and provide more reliable guarantees for the green and safe development of modern industry.

1. Observe the strength of corrosiveness

If the oxidizability of the medium exceeds the corrosion resistance limit of conventional stainless steel (for example, concentrated sulfuric acid contains chloride ions or dry chlorine gas), a fully lined fluorine-lined plug valve must be selected to achieve "absolute anti-corrosion". If it is only a weak acid, weak base or ordinary aqueous solution, a soft-sealed plug valve can meet the requirements and is more cost-effective.

2. Check whether the medium contains solid particles

When the solid content in the medium is greater than 1% and the particle hardness is relatively high, the soft-sealed plug valve has better wear resistance due to its self-cleaning groove and elastic bushing. However, fully fluorine-lined valve seats are prone to being scratched by hard particles. In such cases, it is advisable to consider switching to a hard alloy valve core or reducing the frequency of use.

3. Check the temperature and pressure

Fluorine-lined plug valve: The upper limit of the long-term operating temperature is generally 150℃, and it can reach 180℃ in the short term.

Soft-sealed plug valve: Depending on the material of the bushing, it can cover a wide range from -196℃ (cryogenic conditions) to 300℃ (high-temperature type), but the pressure usually does not exceed PN25.

If both high temperature and high pressure are faced simultaneously, it is necessary to evaluate whether to choose metal seals or special reinforcing structures.

4. Check the purity requirements of the medium

In industries such as electronics and pharmaceuticals, where the precipitation of metal ions is required to be extremely low, fully lined fluorine-lined plug valves must be selected. If there are no strict requirements for ion precipitation in food-grade working conditions, food-grade soft-sealed plug valves can be selected to reduce operating torque and equipment costs.

5. Check the operating frequency of the valve

For applications that require frequent opening and closing (such as more than 500 times a day), soft-sealed plug valves can significantly extend the service life of the actuator due to their low friction coefficient and small operating torque. If the medium is highly corrosive but the operation is not frequent, the fluorine-lined plug valve is more economical.

Fluorine-lined plug valves and soft-sealed plug valves are like "special forces" and "all-rounders" in the process industry. The former is known for its "absolute corrosion resistance", while the latter excels in "elastic sealing and wear resistance". In actual engineering, there is no fixed answer to which type of valve to choose. It must be comprehensively weighed based on factors such as the corrosiveness of the medium, solid content, temperature and pressure, purity requirements, and operating frequency. In critical application scenarios, it is even necessary to verify through fluid mechanics simulation and life calculation to ensure the achievement of the operation goals of safety, long cycle and low maintenance.

With the continuous advancement of fluoroplastic modification technology and elastomer composite materials, the performance boundaries of these two types of valves are still constantly expanding. In the future, in emerging fields such as new energy, seawater desalination and hydrogen energy, they will surely demonstrate greater application potential and provide more reliable guarantees for the green and safe development of modern industry.

Previous: Mongolian Customers Visit ZZJG VALVE to Inspect Plug Valves