What is a Lubricated Plug Valve?

In the pipeline system, many industries choose the plug valves as a stable and safe pipeline guard. Among the many types of plug valves, lubricated plug valve can be the king. It has sophisticated switches that control the direction, rate and pressure of fluid flow. Now, they have become an unique choice in many industrial applications with their special structure and excellent performance.

1.Structure & Working Principle

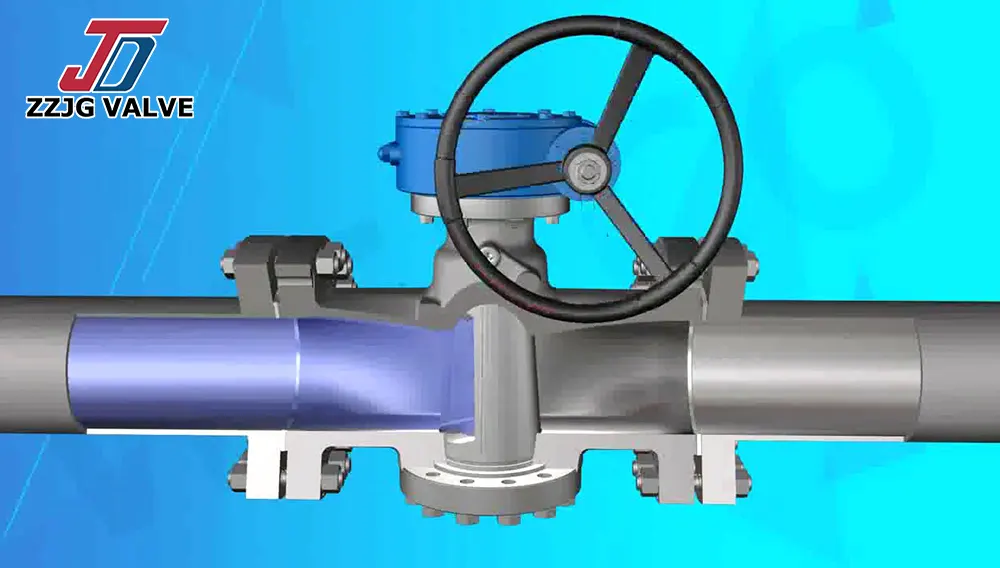

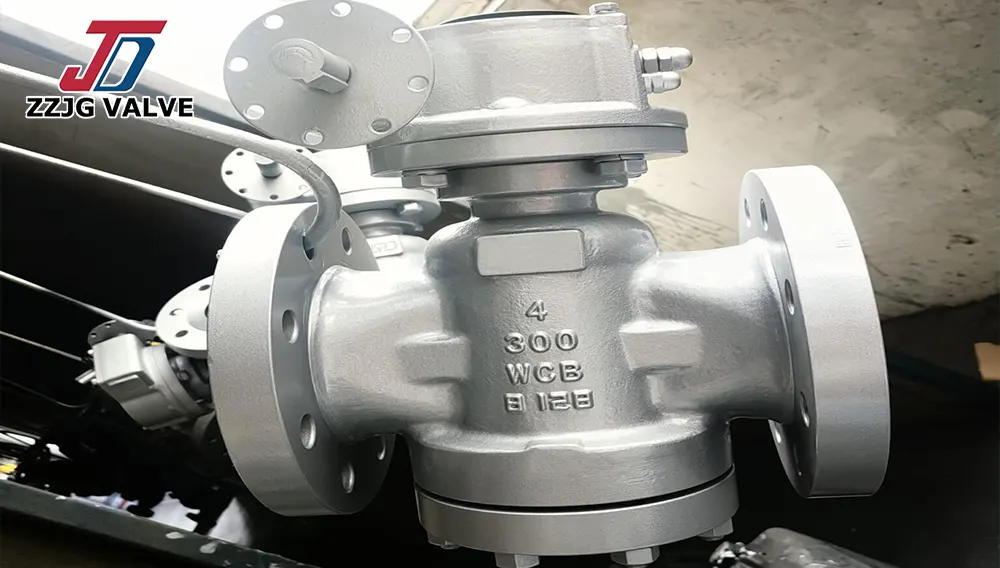

Plug is a core component of the plug valve, lubricated plug valve is no exception. The plug of the lubricated plug valve is also a cone or a cylinder, which can fit tightly with the sealing surface. Generally speaking, lubricated plug valve body is made of cast iron, cast steel or stainless steel, which can adapt to different working media and pressure requirements. To ensure a good sealing effect with the sealing surface of the valve body, the surface of the plug is precision machined and specially treated.

Lubricant is the key achieve lubrication. The lubricant is injected between the plug and sealing surface of the valve body, forming a lubricating film which can reduce the friction and wear of the plug during rotation. Also, it can effectively prevent the erosion of the sealing surface by the fluid medium. Therefore, it has a long service life. The valve body of lubricated plug valve is equipped with a grease injection nozzle, and a high-pressure grease injection gun is used to inject special grease into the sealing chamber. The grease injection port is the location where the grease is injected, and its location is usually at the top or side of the plug valve grease injection.

1.1 Excellent Sealing Performance

Sealing principle of the lubricated plug valve is based on the sealing film formed by the lubricant and the tight fit between the plug and the sealing surface of the valve body. This sealing method enables the valve to achieve almost zero leakage in the closed state. For some industrial processes with extremely high requirements for sealing, such as the transportation of hazardous chemicals and high-pressure gas control in the chemical and petroleum industries, lubricated plug valves can ensure the safe and reliable transmission of fluid media, effectively prevent leakage accidents, and ensure personnel safety and environmental pollution.

1.2 Good Wear Resistance

The injection of lubricant effectively reduces the direct friction between the plug and the sealing surface of the valve body. During frequent switching operations, the lubricating film can continuously protect the sealing surface and reduce the degree of wear. Even in fluid media containing solid particles, lubricated plug valves can maintain good sealing performance and service life. Compared with other types of valves, its wear resistance is particularly outstanding, reducing valve leakage and maintenance and replacement frequency caused by wear, and reducing the maintenance cost of industrial production.

1.3 Simple and Flexible Operation

Structure of the lubricated plug valve is simple. And Operation method is intuitive and easy to understand. The valve can be quickly opened and closed by simply turn the plug through the handle or actuator. This operation mode is not only suitable for manual operation, but also can realize remote control and automatic operation easily after being equipped with an automatic actuator, meeting the needs of automatic control in modern industrial production. What's more, the switch stroke of the lubricated plug valve is short and the response speed is fast. It can be complete the on-off control of the fluid medium in a short time, improving the efficiency of industrial production.

1.4 Wide Range of Applications

Lubricated plug valves can adapt to a variety of working media and pressure ranges. From low pressure to high pressure, from normal temperature to high temperature, from ordinary media such as water and oil to highly corrosive chemicals such as acids and alkalis, lubricated plug valves can be selected and designed accordingly according to different working conditions. Its diverse material selection and sealing structure design enable it to be widely used in many industrial fields such as petrochemicals, natural gas, electricity, pharmaceuticals, and food processing, becoming a valve product with strong versatility.

2.Application of Lubricated Plug Valves

Petrochemical Industry

In field of petrochemicals, lubricated plug valves are widely used in crude oil pipelines, process pipelines of refineries, and storage and transportation systems of chemical raw materials. Since petrochemical media are often flammable, explosive, highly corrosive, the excellent sealing performance and anti-wear performance of lubricated plug valves can ensure the safe transmission of these dangerous media and prevent fires, explosions, and environmental pollution accidents caused by leakage. At the same time, lubricated plug valves can also works stably and reliably on some high-temperature and high-pressure reactor feed and discharge pipelines, meeting the strict requirements of production processes for valves.

Natural Gas Industry

As a clean energy, natural gas occupies an important position in energy supply. In the process of natural gas extraction, transportation, and storage, lubricated plug valves are used to cut off and control natural gas pipelines. Its good sealing performance can effectively prevent natural gas leakage and ensure the safe operation of the natural gas pipeline system. In high-pressure natural gas pipelines, the high-pressure resistance of lubricated plug valves makes it an ideal cut-off valve. At the same time, its flexible operation also facilitates the rapid cutting off of natural gas supply when needed, and pipeline maintenance and repair.

Power Industry

In the power industry, power plants is key application site. Lubricated plug valves are mainly used to control boiler feed water systems, steam pipes, cooling water systems. For example, on the boiler feed water pipe, lubricated plug valve will accurately control the feed water flow, which help the boiler can easily maintainnormal operation; in the steam pipe, lubricated plug valve is used to cut off and distribute steam, as a result it can meet the steam needs of different equipment. In high temperature environment of the boiler and steam pipe, the high temperatureresistance of the lubricated plug valve enables it to work safely and stably, providing reliable valve protection for power production.

3.Conclusion

Lubricated plug valve plays a vital role in modern industrial pipeline systems with its unique lubrication and sealing principle, excellent performance characteristics and wide range of applications. It can not only ensure the safe and reliable transmission of fluid media, improve the efficiency and safety of industrial production, but also achieve long-term stable operation through reasonable maintenance and reduce the operating costs of enterprises. With the continuous development of industrial technology and the increasing requirements for valve performance, lubricated plug valves will continue to play an indispensable role in various industrial fields, escorting the stable operation of industrial production.

If you want to know more or get a quote, please contact ZZJG VALVE.

Previous: General Valve: Key Control in Industrial Processes